Plastic

Featured events:

CHINAPLAS 2026

Booth: 2.1F91 - National Exhibition and Convention Center (NECC), Hongqiao, Shanghai, PR China

SPS ITALIA 2026

Booth F007 - Pad. 3 - Fiere di Parma, Parma, Italy

Smart solutions to shape the plastic of the future

A solid application know-how, the result of over 50 years of experience in the sector, makes Gefran the reference point for the people who operate in extrusion, injection and blowing processes. Our solutions are born from listening to the real needs of the market and combine precision sensors, advanced automation and digital technologies into an integrated and scalable ecosystem. Process reliability, energy efficiency and simplicity of integration: every Gefran proposal is designed to offer concrete and sustainable value to the people who transform plastic into innovation.

Applications of our products

Electric injection machine

Learn about the electric injection moulding process: the cutting edge of injection moulding, with faster cycle times and reduced consumption for increasingly efficient production.

Requirements:

Control of the granule

Learn more

Management of the Hot Runners

Learn more

Temperature control of the barrel

Learn more

Control of the moulding process

Learn more

Injection force

Learn more

Measurement of injection pressure at the nozzle

Learn more

Tie bar deformation

Learn more

Deformation of the moving platen

Learn more

Enhancing Production Data

Learn more

Gefran Services

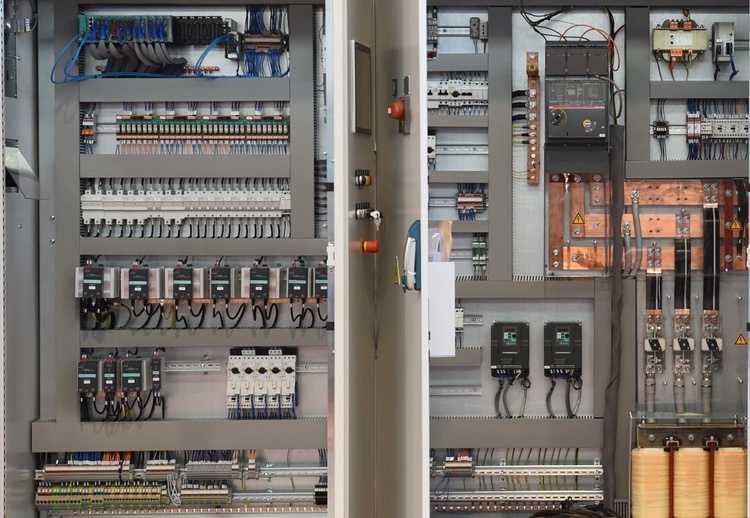

Electrical engineering and automation

Electrical panel construction

PLC software development and supervision systems

PLC software development and supervision systems

PLC programming solutions based on Gefran components, with the possibility of integrating third-party hardware on request, and development of SCADA and supervision systems to ensure advanced control of processes, temperatures, motors and energy consumption.

Installation and commissioning of plants

Advanced remote assistance

Integration with management systems (ERP/MES)

Max and Gaia IoT platform

Max and Gaia IoT platform

Industrial IoT platform, available both in the cloud and on-premise and installable directly at the edge, designed for machine servitisation and increased added value. It allows continuous, uninterrupted monitoring and production optimisation, all integrated into a single solution available both as a purchase licence and as a service managed by Gefran Soluzioni.