Low-pressure die-casting machines are mainly used in the automotive, aerospace and mechanical sectors, where the production of complex and structural resistant components is required.

This process allows the production of parts such as alloy wheels, engine mounts, gearboxes and housings, ensuring high dimensional accuracy and excellent surface quality. Thanks to the low pressure, porosity and internal defects are reduced, improving the mechanical properties of the finished product.

Among the main advantages are high repeatability, reductionin waste and the possibility of obtaining complex shapes with thin profiles, ideal for lightweight but robust components.

Requirements:

Control of electrical heating loads

Learn more

Measurement of thermal process temperature

Learn more

Metal injection pressure measurement

Learn more

Mould position monitoring

Learn more

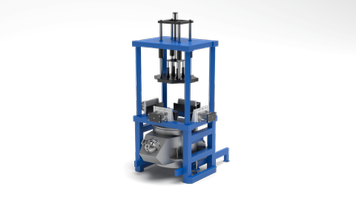

Operating principle

Low-pressuredie casting machines are systems that use a vertical shot process from bottom to top to inject molten metal into a mould. The operating principle is based on the use of a furnace, located under the structure that houses the mould, in which the metal – usually aluminium or magnesium – is kept at a constant temperature (around 700°C) to ensureits fluidity during the injection phase. The injection phase takes place by applying controlled pressure in the furnace chamber: this pressure pushes the molten metal through a riser tube connecting the furnace to the mould. In this way, the metal slowly fills the mould from the bottom up, reducing turbulence and air inclusions.

The result is the production of parts with low internal porosity and excellent mechanicalproperties. Once the metal has solidified in the mould, the pressure is released, the mould opens and the component is extracted. The process is highly automatable, suitable for mass production, and allows for the creation of complex shapes with thin walls and high dimensional accuracy, ideal for the automotive and aerospace industries .

Requirements and technology

In the low-pressure die casting process, one of the most critical aspects is the holding furnace, which must ensure and maintain the molten metal – usually aluminium or magnesium – at a constant and controlled temperature, avoiding contamination and oxidation.

Injection pressure is also an important factor and must be precisely controlled to allow slow and uniform filling of the mould, reducing turbulence, porosity and internal defects. Furthermore, to ensure consistent and controlled production quality, not only the injection phase, but also the mould opening and closing phases and the extraction of the finished product are managed by automated systems. This is thanks to precise and repetitive movements, which minimise variations in the process and ensure high quality of the final product.