Machines and plants for the transformation of metals

From die-casting presses to sheet metal bending machines, batch heat treatment furnaces and vacuum furnaces, the main technologies for the processing and heat treatment of metals require reliable, precise and high-performance solutions. Gefran provides advanced systems and devices that allow the accurate control of processes, optimise energy efficiency and ensure the highest quality in the final result. Here is complete support that accompanies the evolution of machines in a journey of digitalisation, sustainability and simplified integration.

Metal

Tube bending

Find out how tube bending machines are used to shape metal tubes, creating a wide range of products: from simple ergonomic components to complex fluid transport systems designed for harsh environments.

Metal

Press Brakes

Find out how press brakes are used to bend metal sheets, giving shape to products of all kinds, ranging from automotive components to panels and containers, from building structures to furnishing elements, up to parts for the aerospace industry.

Metal

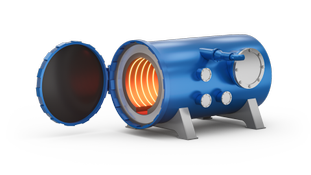

Vacuum furnaces

Find out how vacuum furnaces represent excellence in high-performance heat treatments. They guarantee optimal quality, absence of oxidation and maximum purity of the materials. Ideal for high-tech industries, they ensure efficiency, precision and superior results.

Metal

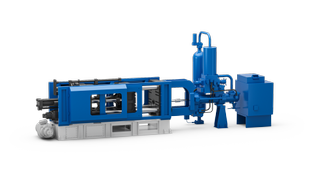

Die casting

Find out the die casting process, an advanced technology for the production of high quality metal components, which guarantees resistant products with complex shapes and reduced weight, for sectors such as automotive, electronics and energy.

Metal

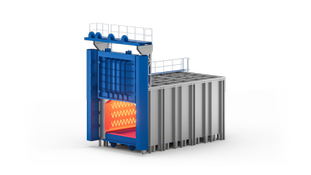

Batch furnaces

Find out the metal heat treatment process, which uses controlled heating to modify the metallurgical structure of the material, so that the end product has the desired mechanical and physical properties.

Metal

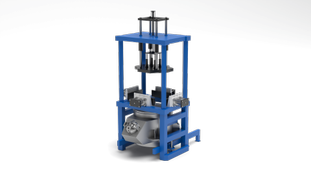

Low pressure die casting

Find out the low pressure die casting process, a technology that involves injecting molten metal into a mould, guaranteeing excellent surface quality, high dimensional precision, reduced porosity and good mechanical resistance. Ideal for complex components in light alloys, such as aluminium and magnesium.

Metal

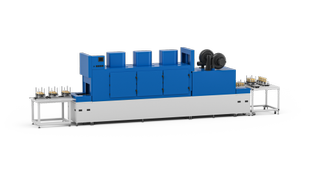

Continuous furnaces

Find out the metal heat treatment process, which uses controlled heating to modify the metallurgical structure of the material, allowing the desired mechanical and physical properties to be obtained.