Heat treatment: the key technology for superior performance

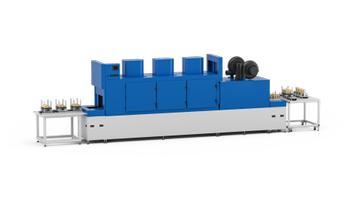

Heat treatment furnaces are essential industrial plants used in a wide range of sectors: from the most demanding ones, such as automotive and aerospace, to the most common applications in precision mechanics and tool production. These systems play a crucial role in the transformation of metal products. Through controlled heating and cooling cycles, the metal changes its internal structure, acquiring the mechanical and physical properties required to ensure high performance, reliability and durability.

Requirements:

Thermal process temperature control

Learn more

Digital recording of process variables

Learn more

High temperature furnace safety threshold

Learn more

Control of electrical heating loads

Learn more

Measurement of thermal process temperature

Learn more