Machines and plants for plastic processing

From extrusion to injection and blowing: the main plastic processing technologies require reliable, precise and high-performance solutions. Gefran provides advanced systems and devices that improve process control, optimise energy efficiency and ensure the highest quality in the finished product.

Complete support to accompany the evolution of machines with a view to digitalisation, sustainability and simplified integration.

Plastic

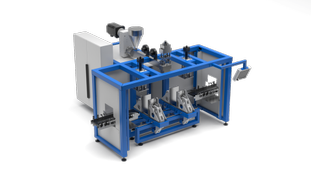

Hydraulic injection machine

Learn about the hydraulic injection moulding process: a versatile technique used to make a wide range of plastic or rubber products, from simple cups or gaskets to complex components such as bumpers for the automotive sector.

Plastic

Extruder

Learn about the extrusion process: a key technology for the continuous transformation of polymers, from the melting of granules to the precise and homogeneous forming of profiles, tubes, sheets or films.

Plastic

Blow moulding machine

Find out the blow moulding process: a complex system of different movements that allows the production of hollow products ranging from a few litres to several cubic metres in size.

Plastic

Thermoforming machine

Find out the thermoforming process: a cutting-edge technology used to manufacture high-quality components for durable or disposable products. Thermoforming machines are primarily used in packaging.

Plastic

Electric injection machine

Learn about the electric injection moulding process: the cutting edge of injection moulding, with faster cycle times and reduced consumption for increasingly efficient production.

Plastic

Blown film extrusion line

Learn about the blown film extrusion process: an advanced technology for the continuous transformation of polymers into stretchable plastic films with specific mechanical properties and excellent resistance, mainly used for packaging.

Plastic

Flat head extruder

Learn about the flat head extrusion process: an industrial solution to produce sheets, films or honeycomb cardboard for multiple applications.

Plastic

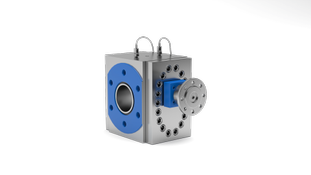

Melt pump

Find out the role of the melt pump: an auxiliary in extrusion processes where the amount of polymer pushed into the die must be constant.

Plastic

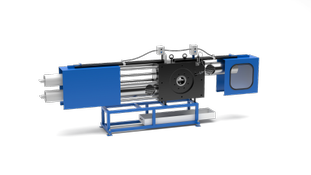

Screen changer

Find out the role of the Screen changer: a necessary auxiliary in the extrusion process when processing recycled materials or when greater polymer cleanliness is required. This operation is important to ensure proper functionality and the safety of personnel and equipment.