Metal

Innovation and expertise at the service of metalworking

For over fifty years, Gefran has put its experience and passion at the service of the people who work with metal and transform it, supporting companies in production and heat treatment processes. Born from listening to real production needs, the proposed solutions integrate precision sensors, power controllers and PID regulators, ensuring accurate control, operational continuity and energy efficiency at every stage of metalworking. Process reliability, quality and sustainability are the values that guide all Gefran proposals, each of which is designed to offer concrete and lasting benefits to the people who build the future with metal.

Applications of our products

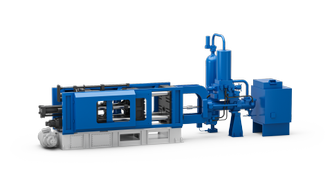

Die casting

Find out the die casting process, an advanced technology for the production of high quality metal components, which guarantees resistant products with complex shapes and reduced weight, for sectors such as automotive, electronics and energy.

Requirements:

Monitoring the closing force

Learn more

Measurement of clamping force distribution

Learn more

Calibration and testing of tie bar deformation

Learn more

Mould position monitoring

Learn more

Monitoring the position of the ejectors

Learn more

Measurement of pressure in the hydraulic circuit

Learn more

Control the electrical heaters of the holding furnace

Learn more

Measurement of the temperature of the holding furnace

Learn more